While at Bose, I was heavily involved in the prototyping efforts pertaining to the friction-mounted hinges and vibration isolation for the camera subsystem.

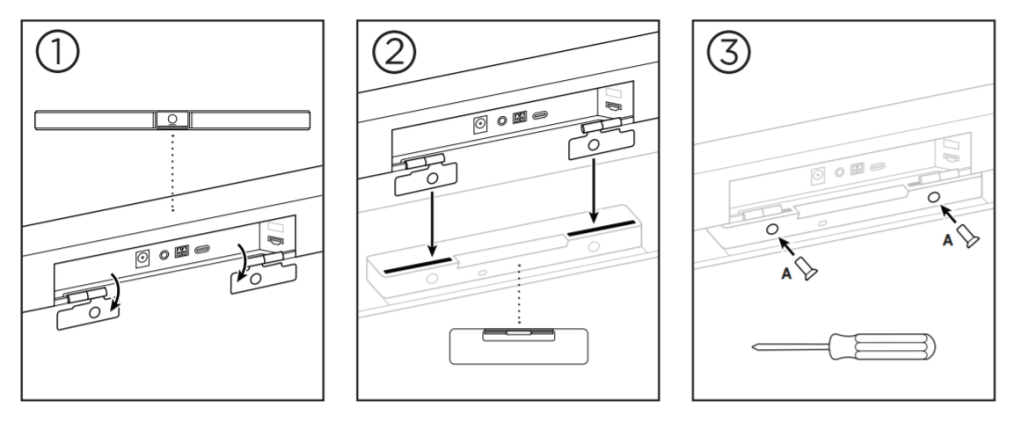

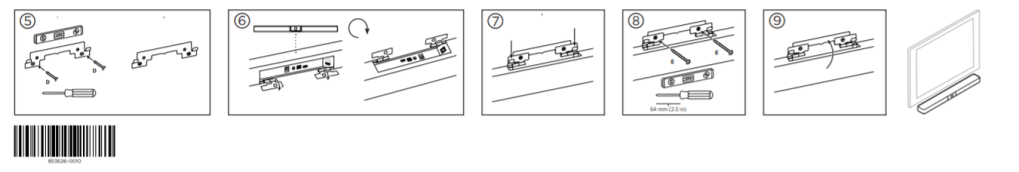

The friction hinges allow a user to sweep the Videobar through a wide range of view, connect to a tabletop or wall mount and mitigate droop over time. A majority of the internal volume was taken up by the transducers and PCBs and the springs couldn’t interfere with the rear ports, so I had to get creative with the connection points. Ultimately, my idea of having the friction hinges serve as a connection point for both the wall mount and table stand minimized complexity and reduced the overall BOM cost, saving the company 10s of thousands.

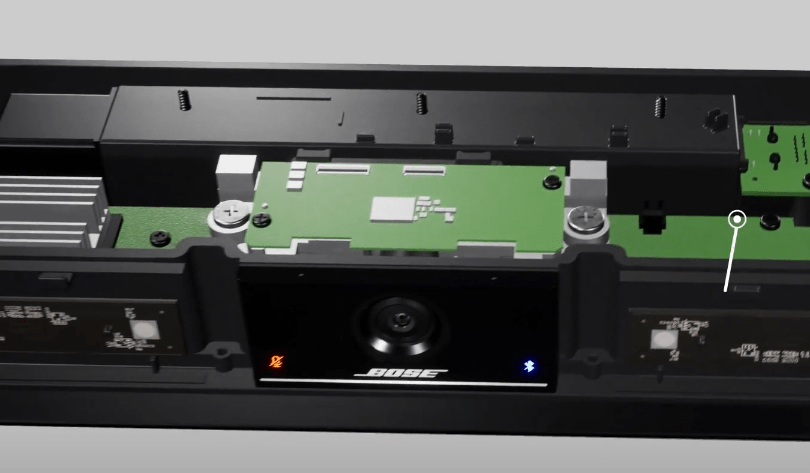

Isolating the camera was not easy given that it was close to several transducers. During prototyping, I iterated on different geometries of high-durometer rubber isolators (traditionally for drones). They had to be stiff enough to not resonate within the frequency band the transducers were capable of producing yet malleable enough to not damage the camera during drops. The final geometry was the happy median and reduced manufacturing complexity by mitigating the need for additional ribbing or compartmentalization.