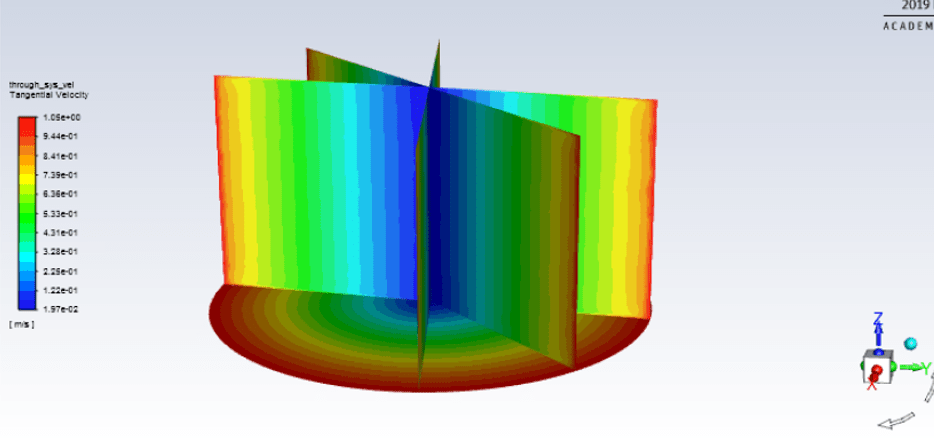

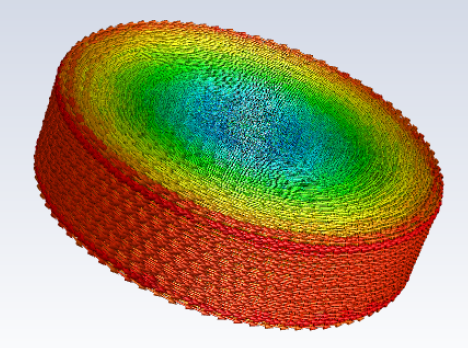

During my Fall 2019 semester, I undertook an independent study under Professor Michael Allshouse to study fluid behavior within an experimental centrifuge. I created numerous 3D ANSYS fluent simulations to gather parameters such as tangential velocity, radial velocity, dynamic pressure, mass imbalance and more. These metrics helped establish the time to solid-body rotation (which means ~zero radial velocity), the stability of the system and reflected inertia through the drive train.

Major Takeaways:

- Time to solid body rotation with 4 radial ribs (~90 minutes)

- Pressure along the length of spindles

- Magnitude of pressure field encompassing both hydrostatic and centrifugal pressure (23.2 PSI)

- Mass imbalance given acceleration rate of centrifuge

Tangential Velocity Contour

Tangential Velocity 3D Vectors

Software Challenges

- Limitation of 512,000 working cells for the student version of ANSYS Fluent

- Difficult to gauge relative roughness coefficient on bottom of drum and inner wall

- Time step size of transient solutions had to be manipulated to balance CPU power and fidelity of solutions

- Hexahedral mesh is ideal for high-quality, quick solutions but difficult to apply over curved surfaces

Dynamic Pressure

On the centrifuge, you will notice that there are radial ribs located circumferentially. These ribs greatly reduce the time to solid body rotation, however, they do induce high dynamic pressures downstream.

Mass Imbalance