Over the course of 6 months, I worked on a team of 5 student engineers to design and build an experimental multiphase centrifuge from ideation to delivery. The genesis of this project was to create a centrifuge that utilized proprietary technology to create far fewer emulsions. Further research was done to see if

My main responsibilities were:

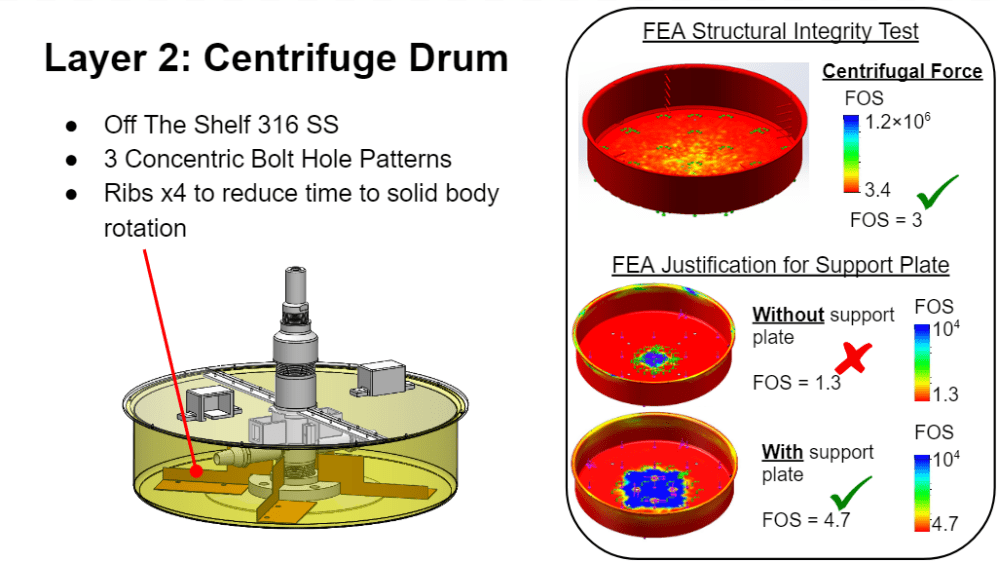

- Structural FEA of system components

- Communicate and negotiate with external vendors on prices for components

- Produce detailed technical reports and presentations to project stakeholders and university staff

- Transient and steady-state ANSYS Fluent simulations

- Designed and conducted experimental verification and validation

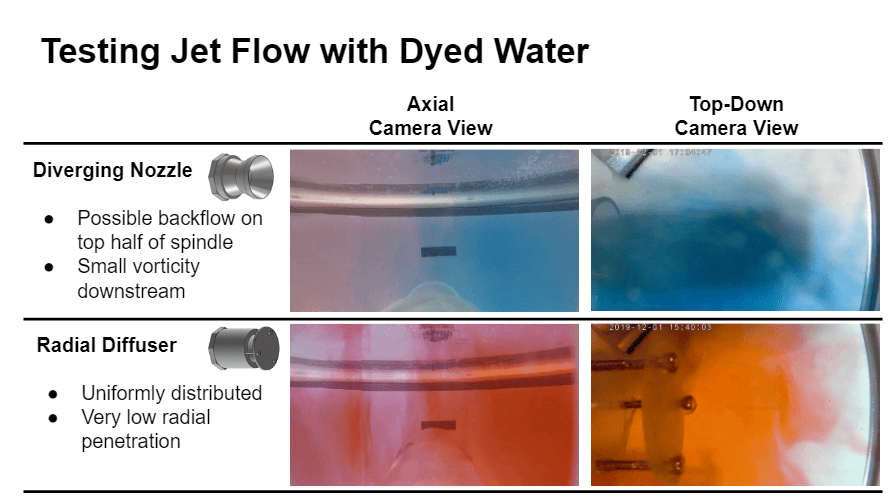

- Performance testing of different spindle end caps to limit emulsions

- frequency simulations to determine the resonance frequencies

- Design and build the fluid movement system

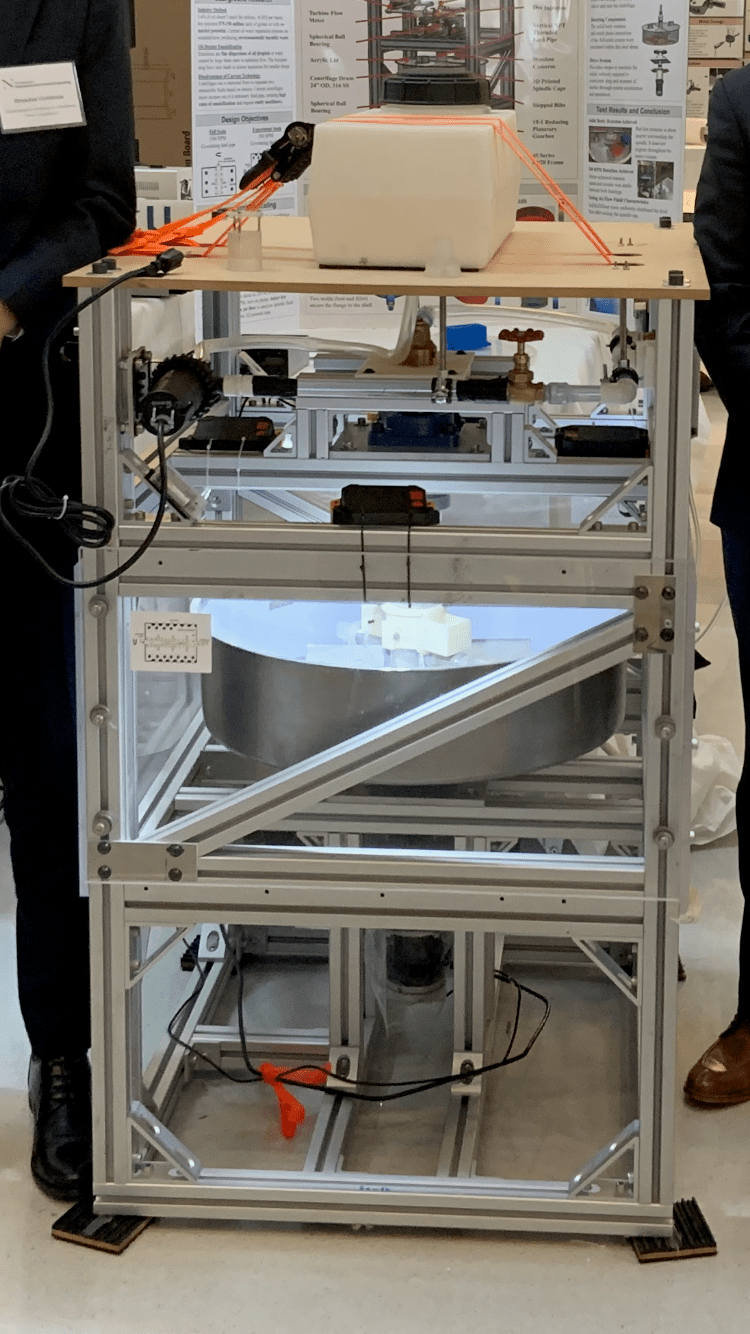

Final Design CAD

Final System

Image taken from News at Northeastern: https://news.northeastern.edu/2019/12/03/robotic-arms-a-device-that-disinfects-your-iphone-and-other-mechanical-engineering-wonders/

Future Considerations:

- More structural FEA of Acrylic Lid to avoid all leaking

- With a larger budget acquiring a variable speed pump

- A single, machined feed pipe connecting the drum base to rotary union

FEA Simulations

The centrifuge drum is the most crucial component as it contains a very intense 18 PSI gauge pressure on the inner wall

The team worked very hard to assure that the induced frequency of 3.33 Hz was no where close to the centrifuge frame’s natural frequency.

Experimental Validation of Success

As seen in the GIF above, small Taylor vorticities are formed just downstream of the spindle endcaps

Presenting to Northeastern University President (Dr. Joesph E. Aoun)

Funding and Support Details

The team’s faculty advisor was Professor Michael Allshouse and the sponsor of the project was Mr. David Park, CEO of Centricrude. This project was overseen and accredited by the Northeastern University College of Engineering.